The Voyager portable gas chromatograph (GC) is designed to provide near real-time, accurate and precise monitoring of environmental remediation activities. The sample media include ambient air, soil vapor extraction and groundwater using headspace analysis techniques.

Mark Collins, Ph.D., Michael Thorpe and Irene M. Burkart

Over the past decade, US environmental regulations have required an increasing number of volatile organic compounds (VOC), both as emissions and in treated wastewater, to meet levels below part-per-billion concentrations. Treated wastewater includes effluent discharge of the water produced by routine operations in refineries and petrochemical plants.

Worldwide environmental initiatives for on-site monitoring have encouraged technologydevelopers to significantly enhance the design of faster, highly accurate, reliable and truly field-portable gas chromatography, to provide signigicant time and cost-savings through accelated site screening and characterization. A current technology innova-tion is the Voyager portable gas chromatograph (GC). The Voyager is a battery-powered, lightweight, miniature hand-held GC, which incorporates a powerful analytical engine for fast screening, and chracterization of toxic airbone VOCs as well as some inorganic gases in workplace areas. In addition, the instrument is designed to monitor headspace of waste-water samples for up to 40 volatile organic compounds (VOC) listed in US EPA Methods 8240.

Technology features

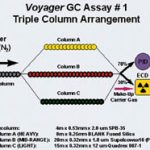

The Voyager weighs just 6,8 kg and incorporates a high sensitivity photoionization detector (PID) together with a miniature electron capture detector (ECD). Voyager’s dimensions are 39 cm long, 27 cm wide, and 15 cm high. Figure 1 shows the Voyager GC carried on the front of the operator’s body to allow both hands free for ascending ladders for on-site plant occupational safety monitoring. A unique internal analytical engine includes a specially designed, miniature stainless-steel valve array for providing fast sample delivery and minimizing sample carry-over (and contamination) due to high sample concentrations. The engine also incorporates a special triple column arrangement with precolumn/backflush and a syringe injection port for headspace sampling of aqueous and soil extract media. The entire internal sampling train, sample loop, GC columns, valves and injection port are heated isothermally at a temperature from 55 °C to 80 °C. The photoionization (PID) and electron capture (ECD) dual detector and triple column configuration is schematically shown in Figure 2. Each column has a precolumn/ backflush flow of carrier gas to maximize baseline stability and significantly reduce carryover of unwanted analytes which would otherwise cause analysis delays.

The instrument is powered by field-rechargeable and replaceable batteries which allow up to 9 hours of in-field use with a 5 hour charge time. Alternatively, the Voyager can be operated from an external 10 to 18V DC power supply, such as a vehicle-battery cigarette lighter receptacle. The instrument can also be operated on AC power.

Voyager can be effectively used to monitor a wide range of volatile organic compounds (VOCs), including chlorinated and aromatic hydrocarbons. The matrices of applicability of the technology include ambient air, soil, soil gas and water. The lower detection limits (LDLs) for VOCs range from parts per trillion (sub-parts per billion) in water matrices to about 25 parts per billion in ambient air, depending upon the type of compound and using both the PID and the ECD.

Analytical results are displayed on the built-in liquid crystal display (LCD), and include both a listing of detected compounds with concentrations and chromatograms. Built-in data logging functions allow storage of up to 40 ten-minute chromatograms or 400 total VOC analyses obtained from a total VOC screening mode of operation. The Voyager GC is European Cenelec EEx ib m IIC T4 (Zone 1) approved as well as Intrinsically Safe, Class 1, Division I, Groups A, B, C, and D in North America, rendering it useful and rugged in confined spaces (tank pre-entry) and other hazardous area locations.

Factory-preprogrammed assays

Voyager can be configured with one analytical method (assay) at a selected time for a number of factory-programmed compounds. Each assay contains compounds relevant to specific industries An environmental assay (Assay 1) contains a selection of 40 com-pounds included in US EPA Method 8240 for chlorinated and aromatic hydrocarbons in groundwater. The software allows the user to add compounds of specific interest to the monitoring requirement.

Each assay includes the compound library, column temperature, pressure (flow rate) and sampling method (internal variable-volume loop or syringe injection).

A new analytical method can be set up by using a PC interface and downloading assay files to the instrument. The PC does not have to be connected to the instrument once the assay has been downloaded to the Voyager.

As an example Assay 2 addresses toxic compounds in the refinery and petrochemical industries. These compounds include benzene, methyl tert-butyl ether (MTBE), tert-amyl methyl ether (TAME), methanol, ethanol, toluene, ethylbenzene, m-xylene, and o-xylene.

Ease of operation

Once the method has been sent from the PC to the Voyager, the instrument can be disconnected from the PC for on-site (field) use and the start/stop key used simply to begin and end analyses as required. All data and chromatograms are logged on Voyager’s internal data logger and will automatically be downloaded on connection to a PC. In a field mode of operation, the instrument can be set to an “user only” mode where the field operator can only access the method parameters by entering a password in the instrument that has been previously set by the supervisor. The Voyager is used as a simple “point-and-press” instrument. The Voyager GC also has a “quick-screen” total VOC mode which utilizes either automatic or manual syringe injection and provides significant time and cost savings when determining which samples merit GC analysis for specification. As with the GC mode, the same 10.6 eV PID lamp is utilized for this mode of operation.

Case study

The instrument was set up for analyzing soil, water and air samples taken from a chemical/rubber manufacturing site, which was known to have high levels of chemical contaminants leaking into the groundwater table. The environmental Assay 1 was loaded into the Voyager GC for this study. The objective of the study was to determine how well the instrument would perform with complex, unknown samples and to gain an insight into the contaminants present on-site.

Samples were introduced into the Voyager GC, either by utilizing the programmable, internal variable-volume loop injection to suit high and low concentrations or by gas-tight syringe injection through the built-in injection port. The variable-volume loop injection variant was applied for air monitoring of emissions from the site, while syringe injections were utilized for headspace sampling of soil, soil gas and groundwater. Up to 1 ml of air sample can be introduced into the GC with either mode of injection to detect true trace concentrations of VOCs.

Photovac

Fax: ++45/48/10 04 00

Further information cpp 258

Unsere Whitepaper-Empfehlung

Wasserstoff gilt als Schlüssel für die Dekarbonisierung der Chemieindustrie. Doch die Nutzung des vermeintlichen Hoffnungsträgers Hydrogen birgt auch Gefahren und stellt die Branche vor neue Herausforderungen, die das gratis Whitepaper „H2 wie Hoffnungsträger?“ näher für Sie…

Teilen: