Girocat combines a catalytic reactor with a rotating heat exchanger. Catalytic oxidation has the advantage of enabling operation to take place at temperatures much lower than thermal incineration. The result is significantly less energy consumption.

Didier Sedaries, Hans Kuttler

The regenerative-catalytic oxidation process known as Girocat works almost residue-free and can be used to destroy volatile organic compounds (VOCs) as well as odorous waste air streams discharged from industrial and food production processes. The amount of external energy needed for the process varies inversely with the VOC concentrations. If the VOC levels are high enough to result in the desired operating temperature, no external energy is required. Even if installed in existing production systems, Girocat can still be used in a very efficient way because of its compact and space-saving design. Later installations in existing buildings are possible without any problems.

Plant technology

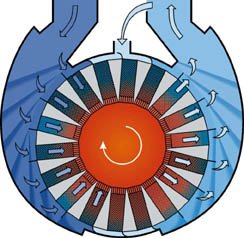

Girocat consists mainly of the reactor/exchanger and a burner with a gas train which is located in the centre (Fig. 1). If small air volumes need to be cleaned, an electric heater can be used alternatively. The reactor/exchanger system features a rotating crown comprising several chambers. Each chamber is composed of the following elements: the outer or heat exchanger zone and the inner zone, where oxidation takes place. Tightness between the different zones of the system (process and purge) is ensured by vertical joints located on both sides of the ceramic blocks.

The catalyst has been selected for its high efficiency with the most common solvents. The ceramic and the catalyst have a honeycomb design, in order to minimise the pressure drop in the system. The motor-driven crown rotates slowly and each chamber moves alternately through the crown’s hot and cold zones. The rotating movement is achieved by two motor reducers driving a toothed wheel via two pinions.

A fan equipped with a frequency inverter exhausts the air from the Girocat system and delivers it into the stack. The system is mounted completely on a steel frame and delivered to the site as a compact unit.

Operational sequence

When the system is started up, it is driven with fresh air until the reaction temperature is reached. The air to be treated passes first through the heat exchanger packing, where it is heated, and then through the first part of the catalyst bed. There, the solvents and odorous substances are converted. Additional heat for start-up and regulation purposes can be added at the centre of the crown. The gas then moves once again through a catalyst bed before flowing through the outlet thermal packing, where it is cooled down to a low temperature. The ceramic/catalyst system has a rotating movement which allows continuous process operation.

A partial air flow taken from the air leaving the incinerator is injected into the intermediate zone. This sweeps any unreacted VOCs remaining in the crown sections towards the catalyst and thereby prevents untreated air from bypassing the system.

Alstom

Fax: ++49/7031/64 32 99

Further information cpp-248

Unsere Webinar-Empfehlung

Die Websession „Wasserstoff in der Chemie – Anlagen, Komponenten, Dienstleistungen“ (hier als Webcast abrufbar) zeigt technische Lösungen auf, die die Herstellung und Handhabung von Wasserstoff in der chemischen Industrie sicher machen und wirtschaftlich gestalten.

Ob effizienter…

Teilen: