Glucose is the most important nutrient source for micro-organisms in biotechnical processes. This carbon source is used in almost 95% of all cultures. The online Glucotrace system allows reliable determination of glucose in bioreactors.

Claus Tollnick, Matthias Beuse

The preparation of increasingly complex products by in some cases genetically engineered organisms in highly sophisticated plants requires comprehensive monitoring of the experimental parameters. Both quality assurance and systematic cost accounting demand not only the analysis of physical parameters such as temperature and pH, but also control and monitoring of chemical variables in the production process, for example glucose.

Instrumental glucose determination nowadays plays an important part in routine analysis. Many laboratory instruments, however, are at present only suitable for offline use, in other words the sample must be provided – and the measurement started – manually. In bioprocess engineering, rapid glucose detection and sterile sampling are aspects of major importance. The online Glucotrace system allows reliable determination of glucose in bioreactors. It is employed industrially for online measurements of glucose at Hoechst Marion Roussel Deutschland GmbH.

Flexible measurement

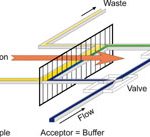

Glucotrace is primarily used for online monitoring of industrial or laboratory cultures which employ glucose as a carbon source. Irrespective of the type of culture (batch, fed-batch, continuous culture), continuous glucose analyses using Glucotrace can be carried out in virtually all cell and micro-organism cultures. The individual analyses are based on the flow-diffusion analysis method, which employs time-dependent sample enrichment (Fig. 1). In this arrangement, the measuring section and the sample or sample inlet are separated from one an-other by a membrane. The measuring section is referred to as the acceptor and the sample side as the donor. In an analysis, the acceptor stream is stopped for a defined time downstream of the membrane, this being effected by valves being switched over to open up a bypass section. The glucose in the sample meanwhile diffuses through the membrane and accumulates in the acceptor chamber. Thus, with time, the concentration of the dialysable sample constituents in the liquid segment of the acceptor will rise.

When this segment is released by the valves switching back, it flows to the detector, where – after an enzymatic reaction of the glucose – it generates a signal (amperometric measurement). The signal intensity is a yardstick for the concentration of the sample. The major advantages of this measuring method, compared with flow injection, are firstly the very wide measuring range, achieved simply by varying the enrichment time, and secondly the long service life of the sensor owing to the separation of the sample and buffer.

Reliably sterile sampling

The analysis of glucose in culture media requires a sample to be taken under sterile conditions from the bioreactor (fermenter), whereby this sample must be both reproducible and relevant. Three sampling options are available in conjunction with Glucotrace:

• filtration probe,

• dialysis probe,

• bypass module.

All the systems enable reliably sterile sampling directly from the bioreactor. The ESIP 5441 filtration probe allows cell-free substrate samples to be drawn from bioreactors. It is secured inside the bioreactor by means of a socket and sterilised in the field together with the medium.

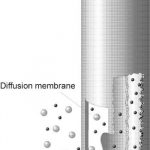

With the dialysis probe, the glucose is transferred via a diffusion membrane into a buffer stream and then transported to the measuring cell with zero-volume sampling. The probe is therefore particularly suitable for mini-fermenters in the field of research and process development. The functional principle of the probe is shown in Figure 2. The entire dialysis probe is made of alloyed steel V4A (DIN 4571) in accordance with the hygienic requirements laid down in DIN EN 1672-2. It is thus suitable for any type of culture. Operation under sterile conditions is greatly promoted by the use of a robust diffusion membrane and thermally stable sealing rings. The bioreactor can be fitted with the probe either via the reactor cover or via a socket on the side.

Field of application

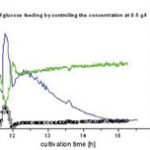

A typical example of how Glucotrace can be used in practice can currently be found at Hoechst Marion Roussel Deutschland GmbH. There, the glucose online system is employed in process development, with the aim of facilitating virtually comprehensive monitoring of the glucose concentration in a fed-batch reactor. The microbial break-down of the glucose is traced over a range from 37 to 0 g/l. A feeding strategy is designed to maintain the concentration at a constant value. Delivering the sample via the ESIP filtration probe allows Glucotrace to determine the glucose concentration at three-minute intervals. Figure 3 shows how the glucose concentration of a fed-batch culture changes over time. The batch phase from the initial concentration of 37 down to 0 g/l is clearly visible. The top-up which is initiated before all of the glucose has been used up causes the concentration to rise slowly back to 5 g/l. Manual correction of the feed gives rise to fluctuating concentrations in the reactor. The advantage of an online glucose system be-comes particularly evident if the offline data (red) is studied. The higher data density due to the online measurement precludes any misinterpretation of the culture’s progress. The offline data alone does not suffice to monitor or control the process in dynamic domains.

Figure 4 shows a glucose feed with precise control of concentration between 0 and 0.5 g/l. After a brief transient phase, a relatively constant glucose concentration is observed over a period of several hours, while the feed rate increases slightly and the dissolved-oxygen level shows a distinct drop from 42 to 6.6%. A sampling interval of three minutes was sufficient to ensure a constant glucose level for the micro-organisms in the bioreactor.

Trace

Fax: ++49/531/2613338

Further information cpp-245

Unsere Webinar-Empfehlung

Die Websession „Wasserstoff in der Chemie – Anlagen, Komponenten, Dienstleistungen“ (hier als Webcast abrufbar) zeigt technische Lösungen auf, die die Herstellung und Handhabung von Wasserstoff in der chemischen Industrie sicher machen und wirtschaftlich gestalten.

Ob effizienter…

Teilen: