The use of infrared optical gas sensors for continuous monitoring of the ambient air has proved to be an excellent method of detecting the potential dangers of flammable gases. The Polytron IR transmitter is equipped with these sensors.

Frank Dallmeyer

Electromagnetic radiation can cause gas molecules to oscillate. The molecules draw energy from the radiation, in other words they absorb part of this radiation. Most flammable organic gases and vapours show this effect at wavelengths of around 3.3 to 3.4 µm. These wavelengths are located in the infrared radiation range and are not visible to the human eye.

A gas sensor with a very simple design will only provide a reliable and unambiguous measurement of the gas concentration under completely stable ambient conditions (Fig. 1). Any change in the intensity of the radiation, for example as a result of changing humidity, dust etc., will also appear as gas concentration.

The usual way to overcome this problem is to carry out a parallel measurement of the radiation intensity at a second wavelength. For this second measurement, a wavelength is chosen at which the measured substance will not affect – i.e. not absorb – the radiation. The measurement at this wavelength produces a reference signal which can be cross-calculated with the signal from the first wavelength. The quotient of the two signals is a measure of the actual gas concentration that is present.

Sensors without mechanical components

This type of sensor is typically equipped with pyroelectrical detectors which react to a pulsed signal. These pulsed signals can be generated either mechanically with a so-called chopper wheel or by electronic modula-tion. The complete lack of any mechanical components has a whole host of advantages in this context, since it increases the sensor’s resistance and reduces the need for costly maintenance, with only periodic calibration needing to be performed. The use of powerful electronics is also an advantage, in that additional parameters – the ambient temperature for example – as well as non-linearities of the detector signals can be evaluated to compensate and linearize the output signal.

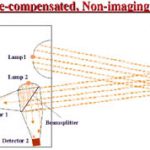

Use of a second light source

This can be achieved by means of a so-called double compensation, whereby two additional signals are used. These are generated using a second light source in addition to the first (Fig. 2).

If the two light sources are arranged such that they emit radia-tion at two different frequencies, and if the light from just one of the radiation sources (i.e. at one of the frequencies) subsequently passes through the cuvette, then both detectors will receive an additional signal from the other radiation source which cannot be affected by gas concentrations. This internal signal serves as a measure of the relative sensitivity of each detector under the prevailing ambient conditions (e.g. temperature).

The transmitter’s electronics produce a signal for each of the two detectors based on the quotient of the signals at the measuring frequency or the reference frequency. As in the concepts described above, the quotient is then calculated from the output signals of the two detectors. This produces a double-compensated output signal, dispensing with the need for regular calibration.

In reality, however, a number of additional parameters also affect the generation of the transmitter signal. For example, non-linearities in the absorption characteristics of the various hydrocarbons need to be compensated by the electronics in order to achieve a linear output signal.

Modem scramblers

Another innovation are so-called modem scramblers, which act like funnels and are used to “bundle” the radiation in front of the detectors. For this purpose the funnels have a highly-reflective surface coating. This results in a number of positive effects:

l This optical set-up requires far less accurate positioning of the various components with respect to one another. As there is no need for an exact image of the light source to be projected onto the surface of the detectors (hence: non-imaging optics), shocks and vibrations will not affect the signals.

l Asymmetrical soiling in the radiation path of the cuvette will not cause unpredictable absorption effects, i.e. a maximum permissible signal reduction of, for example, 70% can occur at any point within the radiation path.

l The radiation inlet and outlet surfaces into and out of the housing are larger, so that greater amounts of dirt will be necessary to cause critical signal reductions.

l Due to the reflection of large parts of the radiation in the funnels, these parts impinge on the wavelength filters in front of the detectors at various angles, thereby widening the measured wavelength. This results in a measurement characteristic which causes the usual, relatively large differences in sensitivity to different target gases to be considerably reduced. This can be extremely helpful, particularly when several different substances may cause a risk of explosion. It also helps to reduce the risk of false alarms if the configuration is set to a small signal substance, while another high signal substance might appear in a non-hazardous concentration.

This optical concept was first made available for industrial gas detection in the Polytron IR. The Polytron IR transmitter also offers a number of additional innovations, such as interfaces with the other components of a gas detection system.

Data transmission via bi-directional digital interfaces

In addition to the analog 4-20 mA interface, the measured values are also transmitted digitally as a HART protocol via the analog interface and/or the RS 485 interface. The two digital interfaces not only facilitate signal transmission, however, but as with Polytron 2 (transmitter for toxic substances), also offer true bi-directional communication for diagnostics and configuration purposes.

Furthermore, the Polytron IR also has a connection for a hand-held terminal as standard (Fig. 3).

Data transmission via the HART protocol

Data transmission to and from the hand-held terminal also takes place via the HART protocol. Thanks to the isolation, the port for the hand-held terminal is intrinsically safe as regards explosion protection. The well-established and widely-used MTL 611B and Psion Organizer hand-held terminals need only be equipped with a plug-in Polytron data module and the MTL-HART interface + cable to offer the same operating and menu structure as the familiar Polytron IR Ex, CO2, N2O and Polytron2 transmitters.

Equally important are suitable mechanical interfaces to the junction box. The Polytron IR comes with either a metric M25x1.5 thread or a conical ¾0 NPT thread. The former is a result of the standard thread adapter fitted in the CEN version.

If a Polytron IR transmitter is to be mounted in pre-installed junction boxes with different thread sizes, a wide variety of adaptors are available on the market for installation accessories.

Stainless-steel housing

When the housing was designed, two requirements were given special attention:

l the housing needed to provide maximum protection in tough environments and under aggressive conditions

l the housing needed to be able to obtain Ex-approvals in accordance with all relevant standards worldwide.

The solution was to use a precision-cast housing made from highest-quality stainless steel (SS 316). This material is also used to withstand the conditions which prevail on offshore platforms, while the IP 66/67 protection rating even allows the detector to be flooded without risk of damage. All the cable threads as well as the back part of the mirror are sealed with an epoxy mould.

Response time

Whereas only the system’s own reaction time (in this case 2 s) is significant if there is an open cuvette and free air flow, lengthy “dead times” can occur if a splash guard or a dust filter is fitted and/or if measurements are to be carried out in stationary air. Two measures were employed to reduce these dead times:

l Two powerful heaters integrated into the mirror fixture ensure that there is always a difference between the cuvette temperature and the temperature of the ambient air. This creates a so-called “chimney effect”, whereby rising warm air generates a constant flow through the cuvette (at the same time the heating prevents any condensation from forming on the window or mirror surface).

l The air is channelled through the splash guard in such a way as to fully exploit this chimney effect. The air flow forces out any other air already in the cuvette, and then flows from the mirror to the window before itself leaving the cuvette.

Water, which may well enter the outer part of the splash guard, is drained off through the cuvette cover and then exits through the front openings at the bottom of the splash guard.

No need for calibration

As already mentioned, there is no need to calibrate the Polytron IR at regular intervals. Internal company regulations, performance testing or configuration for special substances, however, may require the applica-tion of test gas. This can be carried out easily using suitable accessories, designed to be compatible with the detector’s interfaces.

A flow cell can optionally be fitted in front of the window of the cuvette. The flow cell has an exact volume, and is fitted with nipples for the gas inlet and outlet. If highly concentrated test gas (e.g. 50 vol. % CH4) is then channelled through the flow cell, the resulting absorption and hence the measurement signal are roughly equivalent to applying a normal, low-concentration test gas to the entire cuvette. This procedure cannot be described as calibration, and moreover requires the cuvette to be free of gas molecules when the test gas is applied. However, in some applications (in the oil and gas industries for example) this method has proved to be a simple alternative to conventional calibra-tion. Further accessories for optimization specific applications with the Polytron IR are currently being developed and should be available soon, e.g. the dust filter and the duct-mounting kit.

Dräger

Fax: ++49/451/882-3122

Further information cpp 259

Unsere Webinar-Empfehlung

Der Webcast MTP und modulare Produktion bietet eine einzigartige Gelegenheit, mehr über die aktuellen Entwicklungen bei MTP und in der modularen Produktion zu erfahren.

Chemie- und Pharmaproduktion braucht mehr Flexibilität

In der heutigen sich schnell wandelnden Welt stehen…

Teilen: