The online filling unit allows various types of recipients with powdery and bulk materials to be filled continuously. The process is carried out in a hermetic enclosure so that it is also possible to process products which are toxic or which need to be handled under nitrogen.

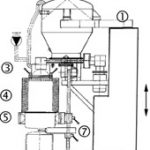

At the end of every production process involving powdery and bulk materials there is a unit for filling the products into recipients. The on-line filling unit separates the filling process from the surroundings and works continuously. By using a double-valve system upstream of the filling head, the tightness of the system is guaranteed. The double valve consists of an active and a passive part that close the inlet and outlet of the filling head tightly and independently of one an-other. The valves are pneumatically driven and require a compressed-air operating pressure of up to 6 bar. The dosing hopper is emptied by means of a simultaneous rotation of the two valves. The inner and outer surfaces of the valves are not linked together during the filling process.

The individual liners consist of a compressed PE tube with a length of up to 50 m. The sterile plastic cartridge is mounted under the valves and outside the filling head. The plastic film is held tight by means of an inflatable seal between the cartridge and the liner that is to be filled. In order to shape the liner, the film has to be extracted little by little from the dispenser by pulling it in its axial direction. After the recipient has been filled, the valves are shut and the liner is closed by means of a clipping or sealing system. A second seal is provided immediately afterwards, just above the first one, to act as the bottom of the next liner.

Compact and mobile

Depending on the size of the recipients used for filling, the dimensions of the machine when installed ready for operation are 925 x 1625 x 2430 to 3000 mm. The entire machine is mounted on a height-adjustable stand, which is fitted with wheels and a brake to prevent it from moving. The height of the dosing hopper support can be adjusted by means of the pneumatic lifting column, so that the machine can be adapted to the size of the recipients to be filled. Thanks to this device, the equipment can be easily dismounted and cleaned. The filling unit is fixed on a turnable stand.

The dosing hopper with the agitator is funnel-shaped and has a maximum powder capacity of approximately 350 l. The bottom of the dosing hopper is fitted with two parallel screws of differing sizes for dosing and conveying the powders to the filling station. The large screw permits rapid dosing of the powder and the small screw precise dosing. With this system, a 25 l recipient can be filled in one minute. A filling capacity of up to 1500 kg/h can be achieved. This capacity can be increased if necessary by using a larger dosing-screw. The recipient is then positioned on the weighing scale by the roller conveyor. The weight of the powder that has been filled in can be determined within a tolerance of 6 10 g and electronically controlled. Depending on the process and the product, the dosing hopper can also be directly replaced by a mixing hopper and the dosing-screw by another mixing and conveying system.

GMP and CIP conformity

Cleaning and dismantling are straightforward, thanks to the turnable, flexible elements of the installation and to the tri-clamp connections. The equipment can be mounted on wheels in order to move it more easily. All the materials used to manufacture the equipment and the machining work itself are in accordance with GMP standards. The equipment can optionally be supplied with an explosion-proof type of protection. The dosing hopper can be cleaned in place. The hopper wall can be cleaned with water using the two rotating fan nozzles inside the hopper.

Prodima

Fax: ++41/21/6 35 77 88

Further information cpp-279

Unsere Whitepaper-Empfehlung

Wasserstoff gilt als Schlüssel für die Dekarbonisierung der Chemieindustrie. Doch die Nutzung des vermeintlichen Hoffnungsträgers Hydrogen birgt auch Gefahren und stellt die Branche vor neue Herausforderungen, die das gratis Whitepaper „H2 wie Hoffnungsträger?“ näher für Sie…

Teilen: