Perfluoroelastomers have an excellent chemical and thermal resistance. During operation, however, O-rings produced in some of these materials are subject to significant permanent deformations leading to leakage. By measuring the compression set it is possible to establish the variations in the elastic resilience of different qualities of elastomer.

Gerhard Buch

Perfluoroelastomers (FFKM) have be-come common in sealing technology for applications involving very exacting chemical and thermal requirements. FKM materials are fluoroelastomers with single fluorine, perfluoroalkyl or perfluoroalkoxy substituents in the polymer chain. In the case of perfluoroelastomers (FFKM) these groups consist exclusively of the above-mentioned substituents. In the chemical industry O-rings made of FFKM can, for example, be found in contact with aggressive media in agitators, pumps, measuring instruments and valves (Fig. 1). If a rubber elastic alternative to PTFE is required, perfluoroelastomers offer a similarly comprehensive chemical resistance with a more or less permanent resilience. The elasticity of this material enables it to be used as a self-sealing element, because the „cold flow“ associated with PTFE, e.g. the plastic deformation under a purely mechanical load, practically does not occur. The Parofluor(r) perfluoro-elastomer range of materials includes eleven different compounds. In addition to the application-specific recipes, two standard qualities are available, namely V3860-75 (white) and V8545-75 (black). The „HifluorTM“ material class, a fluoroelastomer with the standard compound V3819-75, offers a chemical resistance in most media that is comparable to that of FFKM but with even better elastic properties.

Permanent deformation

Some perfluoroelastomers exhibit no permanently good elasticity and suffer permanent deformation, especially under thermal loading. Cyclically fluctuating operating temperatures, as for example with mechanical seals in intermittently operating pumps, increase the danger of permanent deformation.

The compression set is a measure of the loss of resilience in an elastic material. In practice, a large compression set means a loss of sealing capacity and an increased risk of leakage. A loss of resilience can be caused by physical or chemical processes in the elastomer. The physical relaxation is mostly reversible and occurs as a result of the rearrangement of the molecule chains with mechanical loading. The chemical relaxation – splitting of the polymer chains or cross-linking points – is very much dependent on temperature and in practice usually only becomes perceptible at high temperatures.

Compression set measurement

The compression set measurement is specified in ASTMD395/DIN53517 and is normally carried out in the laboratory at constant temperatures. It is dependent on the test time, test temperature, initial compression and geometry of the sample. For comparing different materials, it is important to carry out the test on uniform specimens.

One typical test entailed measuring the resilience of O-rings with a cross section of 3.53 mm and different initial compressions. The duration of the test was 70 h at a tempera-ture of 200 °C. Low initial deformations resulted in a particularly large compression set (Fig. 2). By optimising the recipe, e.g. as with Parofluor V8545-75, it was possible to considerably reduce the sensitivity compared to low initial compressions.

The coefficient of thermal expansion of perfluoroelastomers is high when compared with other elastomers. The average for FFKM materials is 300*10-6K-1, for example, as against approx. 100*10-6K-1 for nitrile butadiene rubber (NBR) and approx. 200*10-6K-1 for FKM.

Figure 3 shows the finite element calculation of the mechanical stresses that occur in a compressed, perfluoroelastomer O-ring cross-section on account of thermal expan-sion. The severely fluctuating stress condi-tions with cyclically alternating temperatures assist the sliding movements of the macromolecules in the elastomer and thus contribute to the permanent deformation.

Cyclic temperature test

The differences between the compression set determined at a constant temperature and the operational behaviour of O-rings in practice served as a basis for a cyclic temperature test. For this test O-rings with a cross section of 3.53 mm were compressed by 16% and subjected to different temperature cycles. After two and five cycles, the compression set was determined half an hour after release at ambient temperature.

In addition to the standard V8545-75 Parofluor and the HifluorTM V3819-75 com-pounds, the test also included three conventional perfluoroelastomers. Figure 4 shows the percentage compression set. With 44% after five cycles HifluorTM V3819-75 exhibits the smallest compression set, followed by Parofluor V8545-75 with 63%. The figures for perfluoroelastomers A, B and C are between 71% and 85% after five cycles. Consequently, Parofluor V8545-75 has a smaller compression set with cyclic temperatures as well as the lowest sensitivity to small deformations. Only HifluorTM V3819-75 has a greater resilience with cyclically alternating temperatures.

Computer simulation of the compression set

The compression set is an indirect parameter that provides information about the long-term behaviour of a seal. If the relaxation characteristics of an elastomer material are known, it is possible to determine the compression set by computer.

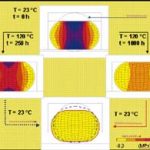

Figure 5 shows the results of a simulation of the compression set process using a finite element calculation. The O-ring is subjected to 20% compression at ambient temperature, with the different colour shades showing the resulting stresses.

On the left-hand side it can be seen that the stresses are lower after the O-ring has been loaded for 250 h at 120 °C. If the O-ring is then cooled again to ambient temperature and released, this results in the broken contour at the bottom part of the diagram. It is possible here to recognise a slight permanent deformation.

Increasing the time under load to 1000 h results in a further reduction of the stresses, as can be seen on the right-hand side of the diagram. After cooling to ambient temperature and releasing, there is a significant permanent deformation in this case, corresponding to a compression set of almost 100 %.

Tried and tested in practice

The good test results are confirmed by practical experience. Parofluor V8545-75 is a very suitable material if the requirements with regard to temperature, chemical resistance and compression set are stringent. As a „dynamic“ O-ring in mechanical seals, Parofluor V8545-75 seals with a low compression despite fluctuating temperatures and aggressive chemicals.

Parker Hannifin

Fax: ++49/7144/23749

Further information cpp-205

Unsere Webinar-Empfehlung

Die Websession „Wasserstoff in der Chemie – Anlagen, Komponenten, Dienstleistungen“ (hier als Webcast abrufbar) zeigt technische Lösungen auf, die die Herstellung und Handhabung von Wasserstoff in der chemischen Industrie sicher machen und wirtschaftlich gestalten.

Ob effizienter…

Teilen: