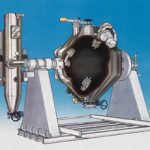

Thanks to a specially designed chopper device integrated in the high-vacuum, rotary Criox dryer, it is now possible even to dry and powder products with a tendency to form lumps. This system, which has a worldwide patent, enables the numerous advantages of the familiar technique to be exploited in a new field – drying fine chemicals with any composition.

Dipl.-Ing. Rolf Ordelheide

The traditional bicone dryer, which has been in use for many years, has the advantage that the cleaning procedure is very straightforward. The dryer is unloaded simply by opening a butterfly valve on the underside. The product is unable to settle because there are no edges or chamfers. The dryer can be cleaned and rinsed from inside very easily, either by rotation (including the chopper) with a liquid dependent on the product or using a special CIP (Cleaning In Place) device. Another advantage of the bicone dryer is that it is thermally homogenous. The product is permanently in a state of turbulence, so that the thermal treatment of the entire wet batch is identical. The product is therefore homogenous.

Other technical advantages

All Criox dryers are equipped with heated manways or openings for loading, which helps to improve their thermal homogeneity.

The energy input to a Criox dryer is less than for dryers with a fixed position, where additional transport power is required for the product itself. A bicone dryer mixes the product perfectly, merely by rotating the cone.

In the past, one disadvantage of bicone dryers was that certain products could form a “ball”. This led to very long drying procedures, because the inside of these balls also needed to have the specified humidity. The second step in the production cycle was always pulverisation of the product. This can now be dispensed with thanks to the Criox dryer with its worldwide patent, which has its cutting device inside the rotating dryer. The chopper permits practically any grain size to be achieved for a variety of products. Before this chopper was suitable for installation, it was necessary to develop an explosion-proof slipring, to enable it to be supplied with power in the rotating area.

The slipring allows also measurement signals to be transmitted from the rotating part. This major advantage allows the temperature to be permanently recorded, for example, and covers to be checked to ensure that they are properly closed, so that accidents can be prevented. The Criox can be supplied with additional measurement signals on request. Continuous process monitoring thus be-comes a possibility. The Criox technique allows specific production parameters (such as the heating temperature, vacuum, rotational speed, temporary operation of the dryer or chopper and liquid or gas that is withdrawn or supplied) to be stored and reproduced again later if required. Approved drying processes can thus be reproduced at any time. This is important in connection with the GMP (Good Manufacturing Procedure) approval for specific batch processes in the phamaceutical industry.

It is even possible to supply air inside the rotating part of the dryer cone for operating butterfly valves or vibrators – a feature which could prove useful for final cleaning.

A wide range of filter products is available for achieving the required particle sizing inside the dryer. The standard filter takes the form of a basket, which can be equipped with a sleeve made of different kinds of fibre (fabric or possibly metal). Furthermore, the supplier could install a complete Goretex filter cartridge, which will facilitate a relatively large filtering surface within a small area. However, these filter cartridges are unable to extract particles that are only a few microns in size.

This process can be followed by filtration of the total balance, possibly with an external cyclone combined with an external filter. The Criox dryer is designed for a vacuum of less then 1 torr. This means that drying can take place at comparatively low temperatures, which is often important for sensitive products in the pharmaceutical industry.

Criox dryers have been used successfully for many years for various product batches between 100 and 6000 l. Since 1997 they have also been available in a glasslined material, making them even more versatile.

Criox dryers for GMP applications

In addition to the dryer advantages described above (straightforward discharge and cleaning), it is also necessary to provide a large inspection door for easy entrance. It is then possible to carry out the SWAB test, as recommended by the FDA. This door is also heated and therefore has the same thermal condition as the bicone dryer itself.

The entire Criox is simple to clean – the exterior, the inner surface with only a few edges and the vacuum system. The vacuum part basically consists of the suction arm and the inner filter. The filter cartridge can be removed easily from outside, thanks to the bayonet fastener which allows cleaning between two batches.

The complete suction arm can also be easily inspected or if necessary removed. Straightforward cleaning and handling makes it possible to reduce the cycle times between batches and to guarantee a clean product for each individual batch.

The use of a completely closed seal, which also includes thermal insulation, is recommended to permit easy external cleaning and prevent contamination. Any connections that are necessary for valves, choppers or instruments are installed inside this rotating part. The outside of the Criox dryer thus remains completely smooth and easy to clean.

Criox in clean atmospheres

The system can be installed in conventional production areas, complete with a GMP-approved casing. The trend is clearly towards clean rooms with controlled accumulation of dust particles, however. Thanks to the special geometry and the high standard of the casing, the Criox is ideal for such rooms. The dryer can be completely separated from the operating area with the aid of partitioning connections. Only the dryer itself is actually inside the clean room. It can be totally separated by keeping this room under pressure. The Criox can even be suspended from the ceiling. This results in greater handling freedom and additional space for cleaning and discharging.

Filling and discharging the dryer

A special barrel loader, which can be mounted directly on the dryer and then moved into the upright position, is available for small dryers. The product then drops into the dryer. This procedure can be repeated several times in order to fill the system with the required amount of material. Large dryers require a direct docking system, which can be approached very precisely by means of proximity switches. The opening can be selected for loading with a pneumatic valve. The manufacturer’s extensive experience enables an effective solution to be found for any type of connection.

Optimised production with Criox

The wide range of requirements covering the entire scope of production in the chemical and pharmaceutical industries often means that the optimum operating parameters have to be determined by trial and error. There-fore three different test Criox types are available for product batches from 2 to 1000 l. Experienced engineers accompany the test phase and determine the ideal parameters for each process.

Ordelheide technical office

Fax: ++49/6201/24 616

Further information cpp 261

Unsere Webinar-Empfehlung

Der Webcast MTP und modulare Produktion bietet eine einzigartige Gelegenheit, mehr über die aktuellen Entwicklungen bei MTP und in der modularen Produktion zu erfahren.

Chemie- und Pharmaproduktion braucht mehr Flexibilität

In der heutigen sich schnell wandelnden Welt stehen…

Teilen: