The possibility of using a control valve as a differential pressure-based flowmeter is now a reality following the introduction of Nelflow, the digital valve controller. This combined control valve and flowmeter offers precision flow metering, even with difficult media.

Ismo Niemelä

Many industrial processes involve handling problem media, such as fibre suspensions, reject flows, chemicals, pigment slurries, coating colours, effluents, condensates, steam and gases, as well as non-magnetic liquids. It is frequently impractical to meter the flow of such fluids by conventional means, e.g. magnetic meters or orifice plates, due to poor repeatability or premature meter failure caused by the inconsistent or aggressive character of the media. In other cases, such as in large-diameter pipelines, it is neither practical nor cost-effective to measure the flow by such means.

The possibility of using a control valve as a differential pressure-based flowmeter has long been accepted in theory. However, industry was in need of an appropriate low-cost electronic device as well as measurement algorithms capable of capturing data in real time and translating them into repeatable flow measurements over the full operating range of control valve sizes, types and configurations.

The solution arrived with the introduction of Nelflow, the digital valve controller, which when used together with the company’s control valves offers fast response times and accurate positioning. Nelflow enables the firm’s rotary and globe valves to be used both as final control elements and as flowmeters.

The Nelflow system

Transforming a control valve into a Nelflow flow-metering control valve system involves adding pressure transmitters upstream and downstream in the piping, or alternatively installing flanges with pressure transmitters around the valve, and then fitting a Nelflow unit to the control valve in place of the existing controller. The cost of purchasing and operating a Nelflow metering control valve is significantly lower than that of a separate control valve and flowmeter. At the same time, there are important performance advantages, particularly where problem media or large pipe diameters are concerned.

How it works

The core components of the Nelflow system are a control valve, pressure transmitters and a Nelflow valve controller unit, which is configured using the Windows-based Valve Manager software and the HART communications protocol. The Nelflow unit uses the differential pressure, the valve’s position (derived from valve controller travel) and the valve’s flow coefficient (Cv value ) to compute the rate at which media are flowing through the valve.

The valve travel is measured by a position sensor in the valve controller. The Cv values corresponding to the valve opening are stored in the memory of the flow transmitter circuit board; no information is lost, even in the event of a power failure. The calculated flow is transmitted as a 4-20 mA output signal, exactly as with any other flowmeter.

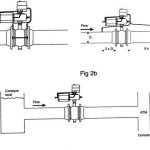

The differential pressure is measured using either pressure transmitter flanges mounted in the immediate vicinity of the valve (Fig. 2 a) or pressure sensors installed directly in the pipeline (Fig. 2 b); if either or both pressures can be assumed to be constant, a constant value is configured using the Valve Manager software, in which case the flow can be calculated without a pressure measurement (Fig. 2 c). The pressure sensors can be any make or model, as long as their output signal is 4 to 20 mA and reasonably accu-rate. The flow calcula-tions use standard valve sizing equations (IEC 60534-2-3). The sensor location can be configured in the unit: higher or lower sensor elevation can be compensated, for example, as can any pressure losses caused by the distance between the valve and the sensor. The repeatability of flow measurements is ensured by exceptionally accurate Cv values and by efficient controller firmware that allows calculations to be performed frequently. Calibration is needed to achieve the maximum degree of accuracy.

Reliability

Nelflow provides repeatability of 60.5%, comparable to that of conventional flowmeters. The system therefore provides a reliable signal for tracking the balance of materials within a process and for automatically carrying out process adjustments based on the metered flow. Using the device simultaneously for flow throttling and measurement has no effect on repeatability. The measurement principle is the established and reliable differential pressure method.

In contrast with conventional flow meters, however, the metering control valve’s performance is virtually unaffected by the nature of the fluid being handled, because differential pressure-based measurements are immune to the problems associated with poor electrical conductivity, excessive air content, fibre suspensions or particles, clogged fluid, coating build-ups in the meter and installation misalignment. The Nelflow meter is capable of measuring both inconsis-tent and non-magnetic fluids, even underextreme conditions.

Wide range of applications

The Nelflow concept can incorporate either rotary or globe valves and is applicable to a wide variety of fluids with no restrictions on pressure, temperature classes or construction materials, as well as being suitable for nominal diameters from 25 mm to 1400 mm or even larger. These advantages offer users ample freedom to select and interchange of valve types without affecting flow measurements.

In addition, whereas conventional flow measurement devices (such as orifice plates and vortex meters) have a rangeability of at most 5:1, the metering control valve can measure repeatably even up to 100:1.

The table above shows a comparison of measuring conditions and metering reliability for magnetic meters, orifice plates, vortex meters and Nelflow.

Retrofitting Nelflow to existing valves

To retrofit an existing valve for Nelflow service, it is simply necessary to install a Nelflow valve controller on the valve, connect the controller to pressure sensors upstream and downstream of the valve and then either configure the system with the physical constants of the medium and the Cv values for the particular valve and pipeline size or calibrate it using another measuring device.

Reduced maintenance costs

Using Nelflow can reduce maintenance costs by over 50%, particularly compared with magnetic meters which may have to be cleaned frequently if the media is “dirty“. A high proportion of traditional maintenance costs actually arise from taking the instrument offline and transferring it to the instrument laboratory. These costs are of course eliminated with Nelflow, because the flowmeter is taken to the instrument laboratory together with the control valve and the two are consequently handled as a single unit. The need for spare instruments is also significantly reduced, because the Nelflow unit can serve as a spare part for all flowmeters for pipe diameters from 25mm to 1400 mm. The total energy consumption is also lower than that of conventional devices (e.g. orifice plates), which constitute an additional constriction in the line, thereby causing higher line pressure and necessitating larger, more expensive pumps.

Neles

Fax: ++358/204/80 58 78

Further information cpp-206

Unsere Webinar-Empfehlung

Die Websession „Wasserstoff in der Chemie – Anlagen, Komponenten, Dienstleistungen“ (hier als Webcast abrufbar) zeigt technische Lösungen auf, die die Herstellung und Handhabung von Wasserstoff in der chemischen Industrie sicher machen und wirtschaftlich gestalten.

Ob effizienter…

Teilen: