Over the past few years, the requirements demanded of gas compressors with respect to environmental compatibility, working safety, gas quality and service life have been getting progressively tougher. The oil-free, hermetically sealed gas compressors produced by a Swiss company meet these expectations.

Beat Frefel

For many gases, contamination with lubrication oil is forbidden. This type of contamination can lead to undesirable reactions or even to explosion. Furthermore, purification – or rather the separation of oil from gas – is often very time-consuming and costly and a residual risk of an inrush of oil remains if the filter is not properly maintained.

Whereas oil-lubricated compressors demand costly re-filtering and monitoring, this can be dispensed with if oil-free compressors are used. Plunger-piston compressors for gases are available both in oil-lubricated versions and as dry runners without oil lubrication and with closed roller bearings.

The application determines the required gas-tightness

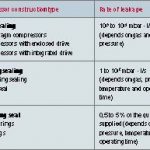

The requirements that must be fulfilled by a gas-tight compressor vary. If the gas is very dangerous or expensive, maximum tightness is demanded. However, there is no such thing as a perfectly gas-tight compressor. The table below illustrates the direct correlation between the design and drive of the compressor and the attainable tightness. With the exception of diaphragm compressors, the Swiss company produces all kinds of constructions.

A high level of flexibility with a very good price-performance ratio is provided by the enclosed drive with the contactless magnetic coupling. It is also possible to produce explosion-protected drives, irrespective of the electrical power, motor voltage or frequency. Gas-tightness is assured for the compressor’s entire service life, as the drive is maintenance-free.

Modular construction

The compressor block and the built-on accessories are constructed in modular fashion to suit the gas, pressure and quantity supplied. The components are sealed with O-rings. Thanks to its simple construction, the compressor is easy to maintain and can be operated with constant gas-tightness. The piping, instrumentation and monitoring of the compressor system are always planned to suit the individual customer’s needs. The design and construction of the piping are a significant factor in the compressor’s gas-tightness and operational reliability.

Certain materials are not allowed to be used in conjunction with certain gases, as they either react with the gas or are not leakproof. It is often necessary to inertise or evacuate the gas compartment completely. When a liquid phase is separated, reliable discharge must be ensured in all operating states and the intake of extraneous gas avoided. The Swiss company’s compressors are equipped with safety and relief valves after every stage. All instrumentation and monitoring tasks are concentrated in one piping block. The piping is internal, which further reduces gas leakage.

Haug

Fax: ++41/71/3 13 99 50

Further information cpp-224

Leakage rates as a function of the compressor design H

Unsere Whitepaper-Empfehlung

Wasserstoff gilt als Schlüssel für die Dekarbonisierung der Chemieindustrie. Doch die Nutzung des vermeintlichen Hoffnungsträgers Hydrogen birgt auch Gefahren und stellt die Branche vor neue Herausforderungen, die das gratis Whitepaper „H2 wie Hoffnungsträger?“ näher für Sie…

Teilen: