The use of one Highflow filter cartridge guarantees not only high efficiency but due to its large filter surface this cartridge also reduc-es the filtration costs to an absolute minimum. Because of a patented radial pleating tech-nique it is possible to get rid of the same dirt load with one 3M 740 B Highflow filter cartridge as with 300 pcs. of 100-string wound cartridges.

Dipl.-Ing. Stefan Mennicken

For the separation of particles between 1 and 20 µm different filter systems are used. If the particle concentration is lower than 10 mg/l filter bags, filter cartridges or filter sheets are used. They all have in common that the filter elements are disposed after reaching their maximum dirt load capacity.

Comparability of different filter systems

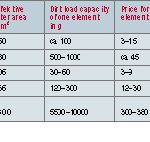

If two or more filter systems guarantee the same filter efficiency their filtration costs will have to be evaluated. The mass of separated particles, the dirt load capacity of one filter element can be used as a first cost indicator. In order to compare the filter systems objectively the parameter „filter cost for one unit separated dirt“ in US$/kg should be used. It does not make sense to compare the filter systems by a parameter similar to „costs per filter area“. The user only wants to know how much he has to spend in order to get rid of certain interfering particles. By using the costs per separated dirt the filtra-tion costs can be evaluated in a first step (Tab. 1). But this parameter takes into account only the pure costs for the filter elements. Besides these costs further cost factors have to be considered.

• Labour costs: The higher the dirt loading capacity of one filter element the longer its life time will be. Therefore only few labour intensive replacements are necessary, which might be dangerous to the operator due to the exposition to aggressive chemicals.

• Disposal costs: Dirt and filter elements have to be disposed after use. Hence, the ratio between dirt and filter element weight is important. How many filter elements have to be disposed in order to separate one kilogramme of dirt? The greater this ratio between dirt and filter element is the smaller the disposal costs will be.

• Product loss: Few filter replacements reduce the product loss to a minimum.

• Plant reliability: A high dirt load capacity prevents a sudden shut down of the plant due to a sudden blockage of the filter elements because of a particle concentration peak. A high filter efficiency protects the down-stream process steps.

Only the addition of all cost factors permits an objective comparison between the different filter systems. It is always essential to look at the amount of the product produced with a certain amount of filter costs. Only the cost comparison of this ratio in US$/ kg product produced can provide the best and the most economical filter solution for the user. But remember only filter systems with the same filter efficiency which produce the same filtrate quality should be compared.

18 m² effective filter area per high flow filter cartridge

The dirt holding capacity which determines the filter life time can only be increased by using a larger effective filter area. Therefore the filter area should be as large as possible. But usually the investment costs increase with larger filter areas because of bigger filter vessels. Due to the development of the 3M 740 B Highflow filter cartridge even small vessels contain large filter areas. The high filter area density (ratio between filter area and vessel volume) has been achieved by a special patented radial pleating technique similar to a Chinese lantern (see figure 1). Because of these special pleats it is possible to realise filter area densities of 315 m²/m³ (126 m² filter area in a vessel volume of 400 l). Figure 2 shows such a filter vessel for seven 3M 740 B Highflow cartridges.

The second impressive feature of this filter cartridge is the high efficiency. Particles between 2 and 70 µm are separated with an efficiency of more than 99%. This efficiency increases the availability and the reliability of a plant be-cause of the well defined protection of the following steps on the downstream side of the process which prevents process disruptions. The 3M 740 B Highflow cartridges are made of 100% polypropylene and comply with the rigid FDA regulations for the food contact of plastics.

Up to 10 kg dirt holding capacity for each filter cartridge

Because of the great effective filter area of 18 m² one single 3M 740 B Highflow filter cartridge can absorb up to 10 kg of dirt. For the same quantity 300 string wound cartridges (100) are needed. Figure 3 shows one 3M 740 B Highflow cartridge in front of the number of standard cartridges needed to absorb the same dirt load.

Success story in the pharmaceutical industry

Due to the high dirt load capacity the user has a great advantage when using this unique filter system. Together with an engineering company a special lay out for a pharmaceutical production site has been designed for the filtration of 40 m³/h of deionised water. Three 3M 743 B Highflow filter cartridges have replaced 22 standard pleated filter cartridges (300). The filtered water is stored in a central tank which provides water for different consumers. In spite of a two step prefiltration using bag filters the pleated standard filter cartridges had to be changed every fourteen days. The three 3M 743 B Highflow filter cartridges have to be changed only every five weeks during the summer. In times of a lower particle concentration the filter life time is even longer. The 3M 743 B Highflow filter cartridge has not only cut the filtration costs down to 25% but has also increased the quality of the filtered water. The former pore size of 3 µm has been reduced to 2 µm. The costs have been reduced down in this way:

• The costs for the filter elements have been reduced by 75%;

• the labour costs have been reduced by 80%;

• the disposal costs are reduced by 80%;

• the availability of the plant has been increased;

• due to a lower pressure drop caused by the 3M 743 B Highflow filter cartridge the investment for new pressure pumps can be saved.

SDI reduction

Another application for the 3M 740 B Highflow filter cartridge is the protection of membranes. The highflow filter cartridge protects the membranes effectively and economically against fouling. In the European laboratory of one of the leading membrane manufacturers these filter cartridges are used for the reduction of the SDI value. They filter ground water which runs through an old pipe system. The SDI is reduced from 3 down to below 1. Even though the 3M 744 B Highflow filter cartridges have to take out iron hydroxide each cartridge can filter 750 m³ before they have to be exchanged. Before the installation of the highflow filter cartridge a multi layer bag filter had to be exchanged every 3 or 4 days. 70 m³ of water had been filtered in that time before the pressure drop increased to its maximum recommended value of 2.4 bars.

Some other applications

Apart from the described water filtration the 3M 740 B is used as a polishing filter for all liquids which contain solid particles and which have a viscosity equal to water. Very good results have been achieved separating catalysts like active carbon or Rany-Nickel. Another application is the cleaning of amine solutions of amine sweetening units in the gas purification of sour gas. The high flow cartridges are often used to filter sugar solutions and waste water.

Loeffler filtration

Fax: ++49/2486/80 98 05

Further information cpp-200

Unsere Webinar-Empfehlung

Der Webcast MTP und modulare Produktion bietet eine einzigartige Gelegenheit, mehr über die aktuellen Entwicklungen bei MTP und in der modularen Produktion zu erfahren.

Chemie- und Pharmaproduktion braucht mehr Flexibilität

In der heutigen sich schnell wandelnden Welt stehen…

Teilen: