For years now, methods such as diverting chutes, impact plates and Coriolis have been employed for measuring bulk material flows. The measuring principle which has been implemented in the ‚Smart Flow Meter‘, first introduced two years ago, has undergone further development based on accumulated experience. Today, these units have achieved a standard which fulfills practically all important requirements.

Dipl.-Ing. K. F. Kistler

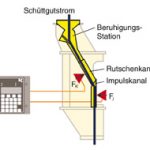

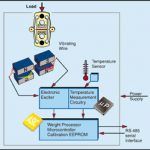

The general areas of application for units which function according to the Smart Flow Meter principle are shown in the table. The main components of this flow meter are shown in Figure 1. The bulk material flow passes through the unit with only minimal diversion. The bulk material travels through three stations – a stabilization sta-tion and two measuring stations. Each measuring station consists of a totally enclosed digital scale, containing a sensor that functions according to the vibrating wire principle with an ASIC (application-specific integrated circuit) and a microprocessor (Fig. 2), as well as a mechanical channel. A filtration process takes place in the ASIC, making the weighing sensor insensitive to critical vibrations. The digital signals of the two scales facilitate an exact calculation of the mass flow per unit of time. As a good illustration, this process can be compared to the way a weighing belt feeder functions. There, the bulk material is transported over a measuring table at a constant speed. The mass flow is derived from the recorded mass and the preset speed. With the Smart Flow Meter principle, the speed is derived from the weighing signal of the second measuring station. As with the weighing belt feeder, both the mass and the speed are known.

The Smart Flow Meter principle has the following advantages:

• accurate due to the high-resolution weighing stations and bypass channel,

• easy on the bulk material due to the practically free flow,

• one-time calibration in the factory,

• permanent free flow, since there are no moving parts.

The capacity of the basic K-SF275 model is between 5 and 200 t/h with an accuracy better than 61% of the actual mass flow. The particle size can be between 0.02 and 10 mm.

Bypass channel

The bypass channel, which is integrated in the same unit, allows the bulk material flow to be diverted around the two measuring stations. The measuring equipment can be tared without having to interrupt the material flow. This can be particularly advantageous if there are major variations in the surrounding environment or substantial accumulations of dust. Depending upon the operational circumstances, this intermediate taring process can be either manual or automated. The time needed for taring is between 10 and 15 s.

Application example: a polyethylene compounding system

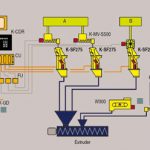

In this particular case, older weighing belt feeders, which required a great deal of cleaning, were replaced by K-SF275 flow meters. Figure 3 demonstrates the basic principle of the system. Blocks A and B depict two separate raw material sources, relatively far apart, which are connected at different times. The bulk material flow capacities range between 15 and 20 t/h. Small quantities of additives are added with weighing feeders. The system detail in Figure 4 shows two flow meters after an operating period of more than six months. The units have been operating without any malfunction since their installation.

Integration in an LDPE system

In this newly installed system, a semi-fini-shed product is extruded and pelletized. The two ingredients, LLDPE and a master batch, are added conventionally with loss-in-weight feeders. Before the manufactured and dried pellets are transported to the packaging line, they slide through the flow meter in order to record the production yield. In this case, the Smart Flow Meter principle is particularly suitable because the pellet flow must be measured gently and the production flow must remain constant.

K-Tron

Fax: ++41/62/8916661

Further information cpp-288

Unsere Webinar-Empfehlung

Die Websession „Wasserstoff in der Chemie – Anlagen, Komponenten, Dienstleistungen“ (hier als Webcast abrufbar) zeigt technische Lösungen auf, die die Herstellung und Handhabung von Wasserstoff in der chemischen Industrie sicher machen und wirtschaftlich gestalten.

Ob effizienter…

Teilen: