New bearing materials and innovative bearings made of ceramic have already won a firm place in chemical and process engi-neering. Extreme hardness and resistance to both corrosion and high temperatures are the out-standing properties of these components.

The typical requirements that must be satisfied by anti-friction bearings in process engineering are lubricant purity, hermetic sealing of the process room from the surroundings, sterilizability and the possibility of superheated-steam cleaning, depending on the application.

More than anything else, the use of conventional anti-friction bearings is limited by corrosion and temperature resistance. If entirely lubricant-free operation is demanded as well, a completely new approach to bearing design is essential.

Hybrid and ceramic roller bearings

Hybrid and ceramic anti-friction bearings use silicon nitride ceramic (Si3N4) as the material for the highly-stressed roller bearing components, ensuring exceptional properties for the structural parts and opening up new applications. The material substitu-tion in the hybrid roller bearing, which is equipped with roller elements made of very light silicon nitride, results in bearings with excellent fast running behaviour. Silicon nitride has only about 40% the density of steel, giving it immediate advantages for spindle bearings with high rotational-speed specifications. Reduced centrifugal forces allow fast-running, hybrid spindle bearings to run with less friction and heating than conventional bearings.

For especially stringent requirements with respect to corrosion and low-temperature resistance, there are also hybrid roller bearings with rings made of the corrosion-resistant roller bearing steels X102CrMo17 and X30 CrMoN 15 1. These bearings are capable of withstanding temperatures of up to 250 °C and are used, for example, in vacuum pumps, turbo-compressors, coating units and mixers. Finally, hybrid roller bearings made of high speed steel, such as HSS S-6-5-2, or nickel-based alloys with possible operating temperatures from 500 °C up to as much as 750°C, are particularly heat-resistant. While steel materials in tribologically highly-stressed contacts, such as in a dry-running bearing, tend to wear down through adhesion, this phenomenon is negligible in the ceramic-steel contacts in the hybrid roller bearings. This explains the excellent properties of hybrid roller bearings under deficient lubrication conditions. At correspondingly low loading and rotational speeds, even completely dry running is possible – something which is essential if the roller bearings are to be used successfully in the high-temperature range above 250 °C, where hardly any form of lubrication still functions.

Bearings for vacuum pumps and compressors

Innovative spindle systems for fast-running turbo-machines in process gas technology or vacuum technology are nowadays often equipped with magnetic bearings, which function practically without friction and which no longer suffer from any rotational-speed limitations. Here too there is a roller bearing, since such bearings are equipped with so-called emergency bearings. In emergency situations, these abruptly cushion the rotor in the event of impermissibly large rotor deflections and guarantee safe running down or passage through critical rotational-speed ranges. During normal operation they remain idle. These bearings are subjected to extreme mechanical stresses, because abrupt accelerations can occur at rotational shaft speeds of n x dm > 1.5 million. Furthermore, lubrication usually ceases to be possible and the bearings are often subjected to corrosive attack by process media or condensate. The hybrid bearing, with its low roller-element mass and low-diffusion friction contact, is far superior to conventional bearings and generally achieves a much longer working life. These bearings are mostly either cageless or designed with steel cages. Corrosion-resistant or low-corrosion roller bearing steels and friction-reducing coatings thereby ensure optimum properties in the face of extreme tribological and corrosive loads.

Ceramic roller bearings for pumps and mixers

The all-ceramic roller bearing is even better suited for dry running and operation in extremely corrosive surroundings. In addition to the roller elements, it also possesses bearing rings made of silicon nitride, which gives it a hardness twice that of a super-hardened steel roller bearing. In addition, the ceramic roller bearing is heat-resistant at temperatures up to or even beyond 800 °C, resistant to almost all ambient media and completely non-magnetic. It is therefore ideally suited for applications in the chemical and food industries. The media present at the bearing can thus be used for lubrication, i.e. ceramic roller bearings also run with media lubrication.

Ceramic roller bearings are therefore often found in hermetically sealed pumps and in mixers with a magnetic drive. Radial-grooved ball bearings and cylindrical roller bearings with an axial and radial design are typical. Materials such as zirconium dioxide (ZrO2) or silicon nitride (Si3N4) can be used for the bearings, depending on requirements. Ceramic roller bearings with rings made of Si3N4 have a slightly better hardness and wear resistance. Nonetheless, there are cases in which ZrO2 is the preferred material, namely when the design demands a material which has an expansion behaviour similar to that of steel. Furthermore, ZrO2 is more resistant to corrosion in certain media.

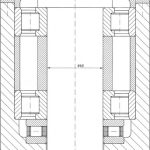

The design of ceramic roller bearings differs only slightly from that of conventional bearings. Mixer bearings with ceramic roller bearings mostly consist of a cylindrical roller bearing and a deep-groove ball bearing with a 3-point geometry as the fixed bearing. This type of bearing, which has a split inner ring and a high contact angle, has a better axial load-capacity than deep-groove bearings. In the event of very high forces, absorption of the radial loads by means of a bearing pair consisting of two cylindrical roller bearings with a high load-bearing capacity is recommended. The additional 3-point bearing then only carries the thrust loads. The design shown in Figure 4 goes a step further: an axial cylindrical roller bearing acts as the fixed bearing instead of the ball bearing. A single bearing is installed if the load direction is fixed; in all other cases, a double bearing is used.

Different thermal expansions of the ceramic roller bearings and the surrounding parts can be offset by means of a number of measures. Carefully designed fits are useful if the temperature range is very narrow. Otherwise, elastic intermediate rings and compensating elements have proved effective as a remedy against expansion.

The hybrid and ceramic anti-friction bearings manufactured by this German supplier are available with bore sizes from 4 mm to an outer diameter of 180 mm. The product range includes deep-groove bearings, angular-contact bearings, cylindrical and spherical roller bearings as well as axial bearings. Ball and cylindrical rollers made of ceramic are also offered.

Cerobear

Fax: ++49/2407/9 62 24

Further information cpp 240

Unsere Webinar-Empfehlung

Der Webcast MTP und modulare Produktion bietet eine einzigartige Gelegenheit, mehr über die aktuellen Entwicklungen bei MTP und in der modularen Produktion zu erfahren.

Chemie- und Pharmaproduktion braucht mehr Flexibilität

In der heutigen sich schnell wandelnden Welt stehen…

Teilen: