The transportation of powders, dusts and granules in the chemical, pharmaceutical and food processing industries necessitates a high-quality, flexible, modular conveying system. If in addition the materials to be conveyed are fine dye powders, coarse swarf lumps, heavy ferric powders or chemicals such as TiO2, new innovative methods have to be developed.

Thomas Ramme

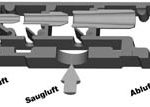

Compared with the frequently complicated and large-scale mechanical designs for creating a vacuum, the functional principle of the Multijector® multiple-stage, compressed-air-driven ejector, is extremely effective. The driving gas p+ enters the pump’s casing and flows through the first nozzle stage. This stage consists of Laval nozzles. First of all, the compressed air is considerably accelerated due to the decreasing diameter in the subsonic-area of the nozzles. Finally, sonic speed is reached at the tiniest diameter of the nozzles.

The widening diameter in the downstream diffuser stage leads to an additional increase in the air velocity in the supersonic area of the first nozzle stage, so that supersonic speed is reached at the outlet of the diffuser stage. The very high velocity correlates with an immense pressure drop, allowing the creation of a considerable vacuum, which is especially important for plug-flow conveying.

The next three or four nozzle stages make use of the high air flow energy to multiply the suction capacity of the pump without requiring any additional energy supply.

In addition to this effectiveness, Multijectors are also unique in that they have no revolving parts, need no lubrication or maintenance and generate no heat during operation. They therefore have an extremely long service life in comparison with conventional pumps or ventilators. The use of new materials for the pumps and the conscious avoidance of plastic parts also help to extend the life-time of the Multijectors, even under rough plant conditions. The revised and improved silencer-system keeps the noise to an acceptably low level.

Product changes easy

The Multijector system allows many different and problematic materials to be transported. Moreover, with the stainless-steel modular design of the new generation, it is easy to convey even different powders or granules using the same kind of conveyor. Cross-contamination is avoided, because all parts which are in contact with the conveyed material can be easily dismantled and cleaned without tools. In addition, the tough material of the filter unit withstands wet cleaning under high pressure or cleaning in an ultrasonic bath. This is especially important for applications in the pharmaceutical and food-processing industries.

Dust-free conveying

The physical principle of vacuum conveying was originally “dust-free” by design, since any dust clouds which develop are sucked in as well. In contrast with pneumatic conveying with positive pressure, the material flow cannot leave the transportation hose or pipe. Various adapter systems ensure that the conveyor is also discharged safely and that no material contaminates the environment. Hence, even extremely fine dusts such as toner powder can be conveyed.

Continuous conveying

In addition to the familiar method of discontinuous conveying, it is now possible to perform continuous conveying with an ingenious combination of two stainless-steel separator containers. This design increases the achievable transport capacities considerably and sets new standards on account of its extraordinary conveying heights and distances. Furthermore, some manifold continuous plant processes require constant suction.

Up-to-date transport capacity diagrams and examples of conveying performance data for products such as manganese dioxide, flame soot, calcium carbonate, sulphur and PTFE powder are available from the manufacturer.

Volkmann

Fax: ++49/2921/6 38 39

Further information cpp 238

Unsere Whitepaper-Empfehlung

Wasserstoff gilt als Schlüssel für die Dekarbonisierung der Chemieindustrie. Doch die Nutzung des vermeintlichen Hoffnungsträgers Hydrogen birgt auch Gefahren und stellt die Branche vor neue Herausforderungen, die das gratis Whitepaper „H2 wie Hoffnungsträger?“ näher für Sie…

Teilen: